Stainless Steel Electropolished Tube (EP Tube)

Stainless Steel Electropolished Tube (EP Tube)

Grade: SS304L, SS316L, SUS316L

Standards: SEMI F19-0304, ASME BPE-2012, ASTM B912-02

Sizes: 1/4" ~ 6" , 6mm ~ 165mm

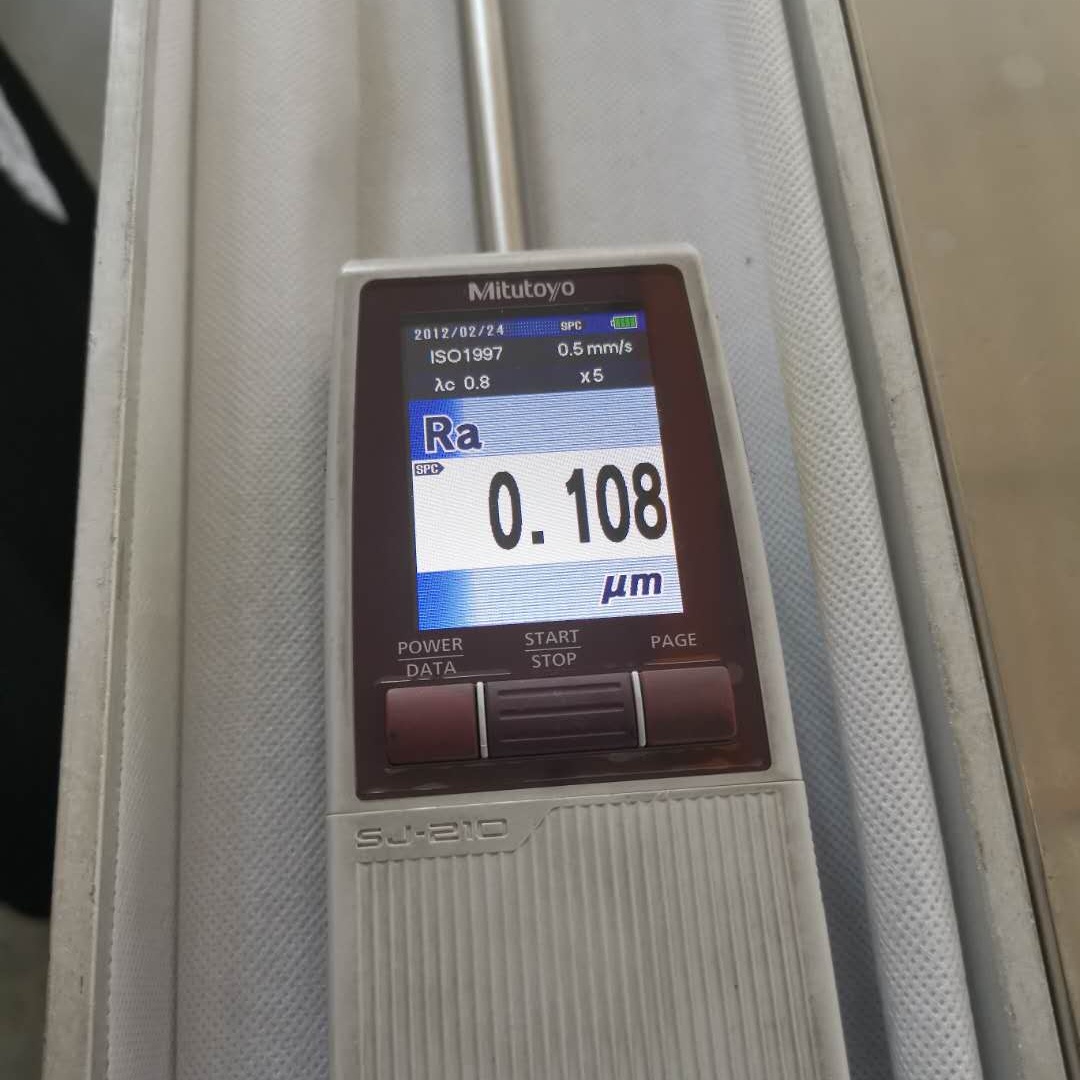

Roughness: Ra≦0.25

Cr/Fe ratio: ≥ 1.5

CrOX/FeOX: ≥ 2.0

Oxide thickness: t ≥ 1.5 nm ( t ≥15 Å)

Application: Pharmaceutical, food and beverage and semiconductor industries, etc.

Electropolishing has become a common process in the production of semiconductors, it’s particularly suitable for polishing the inside surface of small tubes. We produce qualified stainless steel bright annealed tubes and choose those in better condition as raw materials, Electropolishing removes material from a metallic workpiece, reducing the surface roughness by levelling micro-peaks and valleys, improving the surface finish, after passivation, EP tubes would be cleaned by ultrapure water, at last, each tube is purged with ultra-high purity (UHP) nitrogen, then capped, put in double plastic bags and sealed in ISO 6 clean room.

Chemical Composition:

Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

304L | ≦0.035 | ≦1.00 | ≦2.0 | ≦0.045 | ≦0.030 | 8.0~13.0 | 18.0~20.0 | / |

316L | ≦0.035 | ≦1.00 | ≦2.0 | ≦0.045 | ≦0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 |

Feature:

Grade | Mechanical Property | Density

| Specific Resistance (10-8Ωm) | Specific Heat 0 - 100℃ Kj / (Kg.℃) | Critical Temperature of Oxidation Resistance | |||

Tensile Strength (N/mm2) | Yield Strength (N/mm2) | Elongation (%) | Continuous Use (℃) | Intermittent Use (℃) | ||||

SS304L | ≥480 | ≥175 | ≥30 | 7.93 | 72 | 0.5 | 900 | 810 |

SS316L | ≥480 | ≥175 | ≥30 | 7.98 | 74 | 0.5 | 900 | 810 |

Size:

O.D. | W.T. (A) | W.T. (B) | |

In | mm | mm | mm |

1/4 | 6.35 | 0.89 | 1.00 |

3/8 | 9.53 | 0.89 | 1.00 |

1/2 | 12.70 | 1.24 | 1.00 |

5/8 | 15.88 | 1.24 | 1.00 |

3/4 | 19.05 | 1.65 | 1.24 |

1 | 25.40 | 1.65 | 1.24 |

1-1/2 | 38.10 | 1.65 | / |

2 | 50.80 | 1.65 | / |

2-1/2 | 63.50 | 1.65 | / |

3 | 76.20 | 1.65 | / |

4 | 101.60 | 2.11 | / |

5 | 127.00 | 2.77 | / |

6 | 152.40 | 2.77 | / |

O.D. | W.T. | ||

mm | Sch5S | Sch10S | |

6A | 10.50 | 1.00 | 1.20 |

8A | 13.80 | 1.20 | 1.65 |

10A | 17.30 | 1.20 | 1.65 |

15A | 21.70 | 1.65 | 2.10 |

20A | 27.20 | 1.65 | 2.10 |

25A | 34.00 | 1.65 | 2.80 |

32A | 42.70 | 1.65 | 2.80 |

40A | 48.60 | 1.65 | 2.80 |

50A | 60.50 | 1.65 | 2.80 |

65A | 76.30 | 2.10 | 3.00 |

80A | 89.10 | 2.10 | 3.00 |

90A | 101.60 | 2.10 | 3.00 |

100A | 114.30 | 2.10 | 3.00 |

125A | 139.80 | 2.80 | 3.40 |

150A | 165.20 | 2.80 | 3.40 |